Why Vaquform?

With clever design and innovative engineering, Vaquform has made vacuum forming simple.

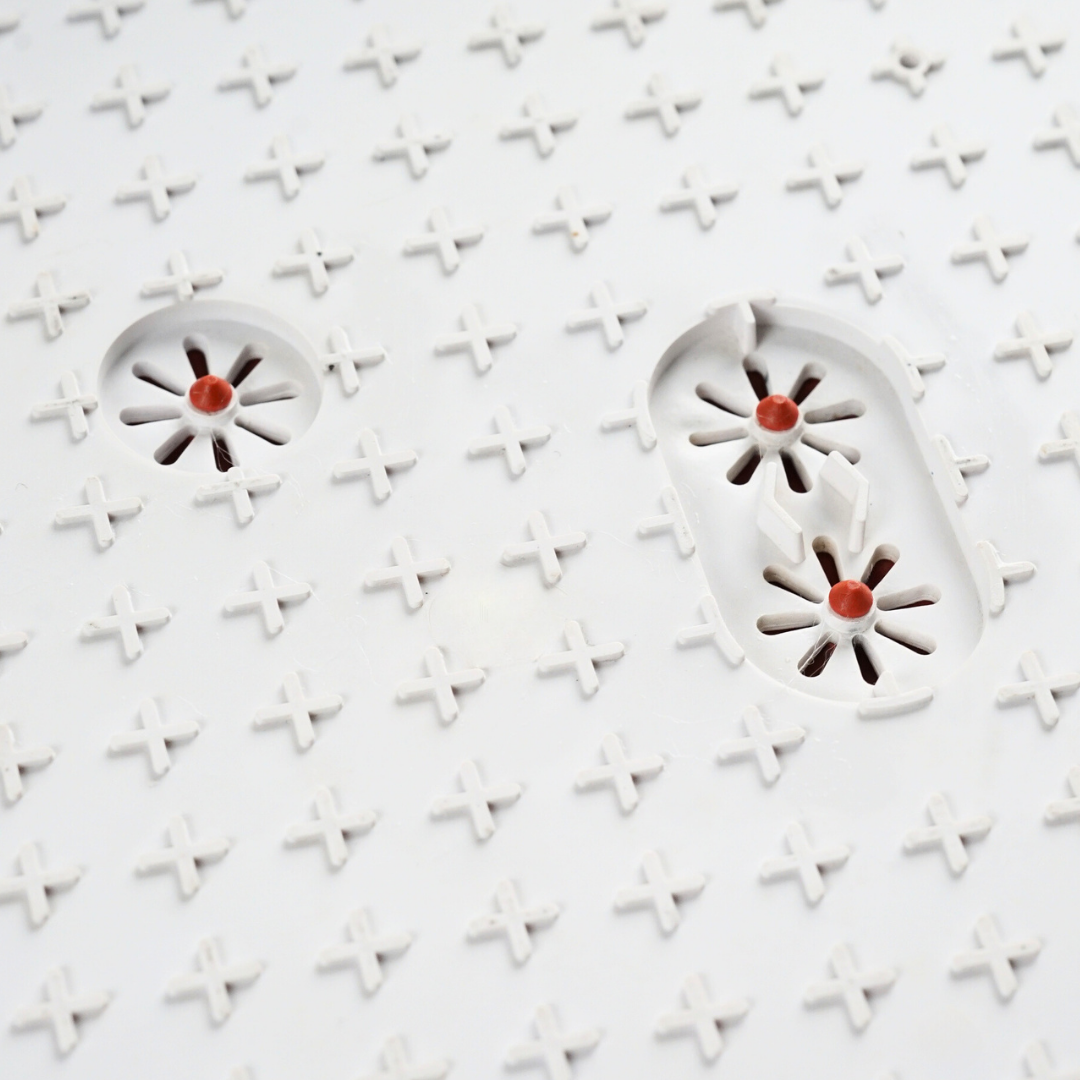

Built-In Hybrid Vacuum

Achieve fine details with powerful -85kPa suction, no external pump needed.

Simplified Interface

User-friendly controls for effortless vacuum forming, even for beginners.

Dynamic Heating

Smart heating technology ensures even results for every project, big or small.

Real-Time Temperature

Stay in control with live temperature monitoring for perfect forming accuracy.

Shaping Businesses

Since our successful Kickstarter campaign in 2017, we've sold thousands of machines. People use them everyday for all sorts of applications in a wide range of industries and interests, for both work and play.

Culinary

Packaging

Dental

Model Making

Film Props

Lighting

Arts & Crafts

Cosplay

Fashion

Product Design

Electronics

Architecture

Interior Design

Agriculture

Medical

Signages

AS SEEN IN